Pumps For Wastewater

Engineered to Keep the Flow Going

Wastewater flows through collection systems to water treatment plants, but in many cases, pumps and pump stations are needed to ensure a steady, secure flow all the way to the wastewater treatment plant and through discharge. But wastewater can be hard to transport and manage with all kinds of waste matter flowing through the system. You need a reliable pump to prevent overflow, spillage, and damage to the environment. At All-Star Products, our wastewater pumps offer superior operational reliability so you keep going no matter what. Our mission has always been unparalleled efficiency, which is why our pumps are designed to offer exceptional performance, long-duty cycles, and very little maintenance.

Our long-lasting, high-powered pumps are specifically engineered to match this kind of demand, help you go longer between duty cycles and make maintenance simpler, and keep you flowing.

Overcome the Challenges of Typical Wastewater Pumps

Most wastewater pumps have been designed to stay on top of regular wastewater flow plus incoming stormwater and surface run-off. This means pumps have to be flexible and ready to accommodate constant fluctuations in inflow. However, there are all kinds of issues that can arise with traditional wastewater pumps, including:

- Pump reliability

- Concerns about energy usage

- Problems with odor, overflow, and spillage

- Ongoing, time- and labor-intensive maintenance

There are all kinds of impacts that can come from a failed wastewater pump or compromised system, including legal, economic, and environmental challenges. As a result? Wastewater pumps must be thoughtfully designed to last and be reliable in the long term.

At All-Star Products, our team is here to transform the way you handle wastewater forever, with pumps providing the required flow going no matter what.

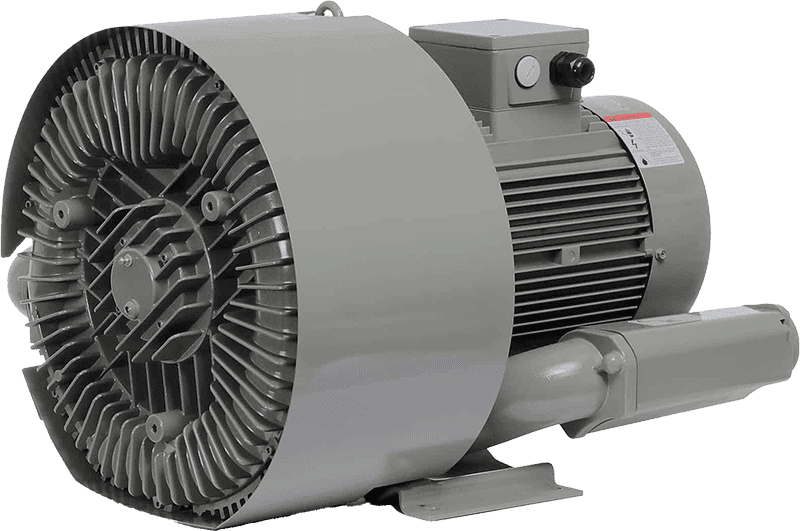

No-Nonsense Pumps for Every Application

Wastewater is notoriously difficult to transport and manage. Organic solids and waste mater can place a lot of stress on typical wastewater pumps. And when you add in the stresses of increased rainfall, flooding, and runoff, the risk of spills and overflows increases, threatening damage to the environment and generate fines.

The three main types of wastewater pumps include:

Centrifugal Pumps

These pumps are equipped to tackle a range of applications, including raw wastewater, flush water, spray water, seal water, primary and secondary sludge, and effluent wastewater with a long duty cycle and a robust pump engine. Often, several centrifugal pumps are used at a single in-plant pump station and move fluid through the pump via the transfer of rotational energy.

Wastewater Pumps For a Steady Flow

When it comes to wastewater pumps, there’s no room for error or issue. That’s why we’re committed to providing you with the right aeration solutions to keep the flow going, take on rainfall runoff, and prevent overflow and spillage. At All-Star Products, that means long-lasting, high-performance pumping solutions that don’t require constant maintenance. Some pump models do not require disassembly for lubrication, which means servicing your pump can be easily maintained.

Our pumps are designed to give you the longest duty cycle possible. Especially when it comes to wastewater treatment, there’s no time for pump maintenance or malfunction. When it comes to managing wastewater, you need to know your pump will work continuously, without unnecessary, labor-intensive maintenance.

Make the most of your environmental applications

with our smart pump solutions.

Here are the most common pumps used

-

TB05-1

- Horsepower (HP): 0.55HP/0.40kW

- Pressure (H2O): 5.9" H2O/14.70mbar

- SCFM: 290 SCFM

- Vacuum (H2O): N/A

- Voltage: 115V/230V

-

RBH9-30-3

- Horsepower (HP): 30.14HP/22.00kW

- Pressure (H2O): 168" H2O/418 mbar

- SCFM: 850 SCFM

- Vacuum (H2O): 148" H2O/370 mbar

- Voltage: 208V/230V/460V

-

RBH84-1105-3

- Horsepower (HP): 11.78HP/8.60kW

- Pressure (H2O): 60" H2O/150 mbar

- SCFM: 600 SCFM

- Vacuum (H2O): 64" H2O/160 mbar

- Voltage: 208V/230V/460V